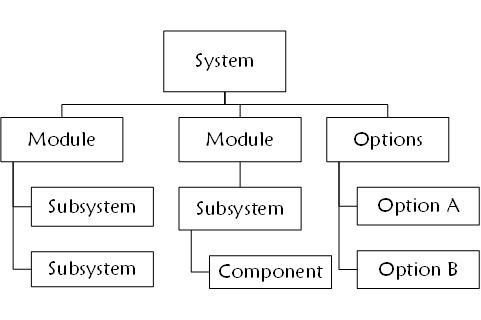

Congratulations! Management has approved the product plan. It’s time for engineering to start designing. First up – arrange the hierarchy of subassemblies on the yet-to-be-born product’s family tree. See the figure below.

Traditionally a capital equipment company’s engineering team will determine a product’s structure based on how they intend to design it. When they finish the design phase, they release it to the company’s materials and resource planning (MRP) system so that systems and spare parts can be quoted, built, and shipped to customers.

But should your product structure only be a consequence of design strategy?

If it is, you’re missing an opportunity to maximize this future product’s commercial success. Product management, manufacturing, and service must all be engaged. They can help define a structure that aligns with how the product will be sold, built, and serviced. Involving other functions sets you up for:

- Better pricing

- Lower product costs

- Shorter manufacturing cycle times

- Lower inventory levels

- Lower service costs

Here’s each function’s role in making it happen.

Product Management

Product management can help the company achieve value-based pricing by using the product’s family tree to tailor the offering to target market sub-segments.

Software and automobile makers are expert practitioners of this strategy. Just look at all the flavors of Intuit’s Quicken or Toyota’s Camry. These are great examples of core products with various configurations designed to target sub-segments of financial software and family sedan buyers. These targeted offerings are only possible because they were structured early in the design process to support them.

Capital equipment makers should take the same approach. Configurations with rifle-like customer targeting can hit the key value drivers. At the same time, you can strip these configurations of features not valued by the target customer. That’s a formula for better pricing and lower costs.

Manufacturing

Manufacturing needs to structure the product to support buying and building the product’s subsystems and components. For example, if they intend to outsource a large subassembly except for a single proprietary part, that single part must be structured separately from the rest of the assembly. In addition to defining product structure to support material purchasing, manufacturing also must structure the product to accommodate assembly and manufacturing test plans. When manufacturing defines their requirements for product structure upfront, you’ll get shorter production cycle times and lower product costs.

Service

A Field Replaceable Unit (FRU) replaces a defective part in a customer’s system. An FRU strategy determines the level of component, assembly, or module sent to the customer for the repair. Service needs to define a product structure that will support their FRU strategy.

For example, suppose there’s an instance where the FRU is a printed circuit board (PCB). However, that PCB is part of a purchased assembly. That PCB must also be structured as a separate, orderable item. Otherwise, when the part fails in the field, you’ll have to order the entire assembly when you only want the PCB. Getting service’s FRU strategy baked into the product structure will keep service costs and spare parts inventory in check.

So, if you want to pluck profit from product structure, don’t just leave its definition in engineering hands. Instead, have engineering work with product management, manufacturing, and service to define the product structure to maximize the product’s commercial success.