Table of Contents

Introduction

Is that new product idea worth developing?

Is product development going according to plan?

Is your new product ready to ship to customers?

Is your product keeping up with market needs?

Is this a good time to cut in the latest engineering change?

Is it time to retire your aging product?

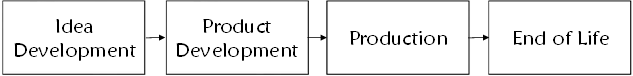

Without a product lifecycle process, it is hard to know. Recall that a product manager coordinates all the activities that ensure a product’s commercial success. The product lifecycle process describes those activities from a product’s beginnings as an idea to its final withdrawal from the market. See Figure 4.

Idea Development

The aim of the idea development phase is to create possibilities for new products. Expect uncertainty in this phase. You may have a sense that a market opportunity exists, but you may not know the exact market definition or product requirements. Similarly, engineering may not know the technical path to address the opportunity. Many more ideas fail than graduate to product development. This high failure rate reflects the stochastic nature of the new idea development process.

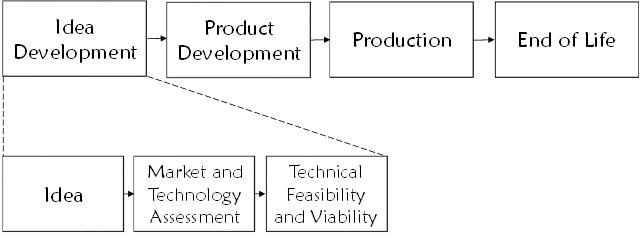

The idea development phase has three sub-phases. See Figure 5.

An idea is any suggestion for a new product or technology. Once an idea is attractive enough for further investigation, it enters the market and technology assessment sub-phase. The market assessment answers questions like:

- Does a market exist that is worth investigating?

- Who are the potential buyers?

- What is the total available market?

- What is the growth rate?

- What is the competitive landscape?

- What are the barriers to entry?

- What is the opportunity to create unique value?

- What are the potential financial returns?

Whereas the technology assessment answers questions like:

- What is the product concept?

- What is the technical approach?

- What are the technical risks?

- What is the intellectual property landscape?

- What is the development effort needed?

- Are inventions required?

If the assessment concludes that the idea is still attractive, but inventions are in the path of success, the process advances to the technical feasibility and viability demonstration sub-phase. Feasibility achievement means that key capabilities of the technology have been demonstrated. Viability achievement means that the key capabilities of the technology have been demonstrated against specific market needs.

Product Development

Product development begins when you find an attractive market opportunity and know the technical path for capitalizing on it. You get to the product development starting line in one of two ways:

- A new product idea that graduates from the idea development phase.

- An existing product line needs improvements to meet customer needs and ensure competitiveness.

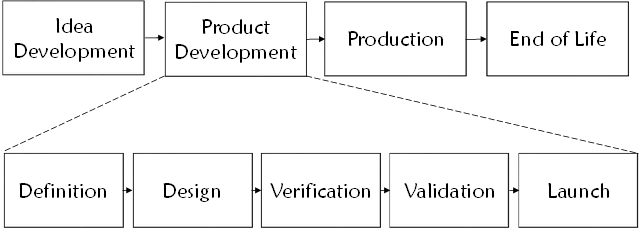

The product development phase has five sub-phases. See Figure 6.

Long development times, changing market requirements, and complex technologies expose capital equipment product development programs to substantial risk. Plus, product development is not an engineering-only activity. Product management, manufacturing, supply chain, service, and other functions make direct contributions. To manage risk and complexity, the best companies:

- Assign a dedicated program manager.

- Embrace rigorous phase gate discipline.

- Identify risks and initiate plans to retire them.

- Clearly define cross-functional deliverables.

For some example cross-functional deliverables for each product development sub-phase, see Table 1.

| Sub-phase | Example Deliverables |

| Definition | Market requirements document Product development plan Core team established |

| Design | Design specification Draft product structure Product design Subsystem verification System verification test plan |

| Verification | Alpha system build System verification test Customer environment simulation test Service plan Production plan Market introduction plan |

| Validation | Beta system build Beta system shipment Beta system customer acceptance Market introduction readiness Production readiness Service readiness |

| Launch | Release to sales Pilot production Field performance Transfer to sustaining engineering |

Production

A product spends most of its life in the production phase. Here, the product team’s focus is on creating and satisfying demand profitably. Product managers must ensure robust, responsive sales support capability. Engineering needs to stay on top of the sustaining engineering backlog. Manufacturing and supply chain must ensure sufficient production capacity and keep costs low. Service must keep customers’ equipment running as advertised.

End of Life

For products, life may end because a replacement product is available, the company can no longer manufacture or service it, or customer demand has fallen. A capital equipment product’s end of life typically occurs in two steps, end-of-production followed by end-of-service. See Figure 7.

Ahead of the end of production, capital equipment companies often give customers an opportunity for a last-time buy. They also give ample notice before ending service to give customers time to adjust their operations.